Definition of Fibercement

One of basic needs of the human is need for shelter. In the beginning, the human being who acted only with the instinct of protection has started to give more importance to the safety, durability, comfort, aesthetics and comfort of the building in the following processes. As the past centuries have provided the development of human beings, they have also accelerated the development and change of the structures in which they live. The change process from stone and concrete building to more lighter and robust steel contruction building continues.

When the building system and culture change, the materials and production styles used in the building also differentiate and develop in order to adapt to this change. Easily erectable, fast and economic solutions are advantageous for final consumers.

Autoclaved fibercement -, which is one of the most effective materials of this process is not only facade cladding material thanks to its flexible structure that can be used in all kinds of structures. Easily acpplicable fibercement sheets that are appropriate to all kinds of architectural plan and texture, be used in all kinds of climate conditions and change face of the building are environment and human friendly.

The fibercement which means ‘fibre-reinforced cement board’ in the literature is generated by passing through of the raw material prepared natural fiber, micronized silica and cement as core ingredients from special machine line, slabbing and then extracting and drying the water inside of it in autoclave furnace.

Furthermore, the fibercement is main raw material of steel construction and prefabricated light building system in particular starting to take place of reinforced concrets buildings in the century we live in.

fibercement started to its production in 2001 under the brand of HekimBoard is currently exported to many countries around the world.

Fibercement Use Areas

fibercement is used in application of exterior and interior wall claddings of all kinds of prefabricated or reinforced concrete buildings, partition walls and separators in the form of sandwich panels, all kinds of ceiling and mezzanine chassis claddings, roof sheathings, all kinds of prefabricated buildings and steel construction building elements.

The fibercement interior and exterior cladding sheets that can be used in all parts of buildings from wall coverings to garden walls is a material used by everyone from construction companies, architects, wholesalers to final consumers due to its price advantage, durability and fireproof properties.

Thanks to ease of use Fibercement application details, it is a maintenance-free natural facade cladding that extends the life of buildings with its wide product range.

Features of Fibercement Cladding Sheets

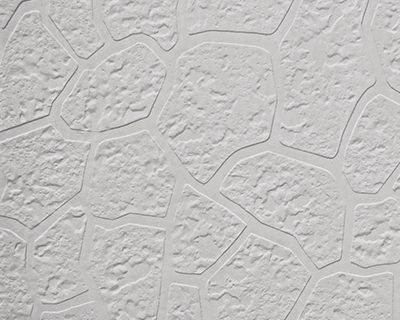

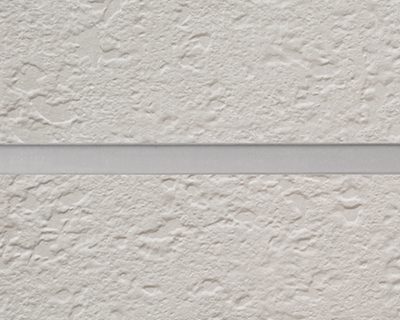

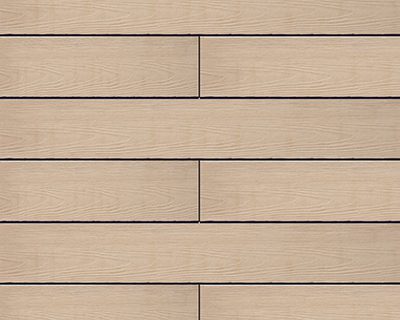

Due to the silica and cement in its contain, it is a high-strength and long-lasting material. The fibercement sheets that can be used safely in the exterior cladding of all kinds of buildings; can also be produced in different decorative patterns such as plain, wood patterned, jointed, siding, stone and adobe. A1 class fibercement that is not affected by water, does not cause humidity, dampness and odour is human and environment friendly also brings trust in the buildings with its inflammability characteristic.

The fibercement enabling the production of the breathing buildings is also resistant to freezing. It can be used in all kinds of cold climate zones. Thanks to its moisture-proof structure, it can also be used easily at seaside and coastal areas. The fibercement sheets are definitely waterproof materials and their water absorbtion rates is lower than the reinforced concrete buildings.

The fibercement being highly resistant to atmospheric conditions due to the materials in its structure and being autoclaved is preferred in all climate conditions.

Furthermore, the fibercement sheets that can be easily processed with suitable tools can meet all needs both aesthetically and architecturally.